Types

Position

Layout

Product Overview

COMPAQ CSCM stress control/field graded mastic tape is engineered to ensure the long-term reliability and safety of medium and high voltage (MV/HV) cable systems. By effectively relieving electrical field stress at critical points, it minimizes the risk of insulation breakdown, partial discharge, and premature system failures.

Manufactured from a thermally stabilized polyolefin blend and reinforced with high-permittivity additives, the CSCM tape provides precise control of voltage gradients around connectors, screen cut-backs, and other stress concentrations. Its self-fusing properties allow it to conform seamlessly to irregular surfaces, ensuring void-free filling, water resistance, and superior adhesion to cable insulation and metallic components. This combination delivers a moisture-tight, mechanically stable, and electrically robust seal that performs reliably under demanding environmental and operational conditions.

By incorporating the COMPAQ CSCM Series into jointing and termination systems, utilities and installers can achieve extended service life, reduced maintenance risks, and improved performance in modern power transmission and distribution networks.

Equilibrates the electric field, reducing stress concentrations in MV/HV applications.

Bonds seamlessly to insulation and connectors, filling voids and eliminating air pockets.

Suitable for both dry and oil-filled environments.

High-permittivity additives manage electrical fields, reducing partial discharge risk.

Conforms easily to irregular shapes and varying diameters.

Maintains performance under continuous load and short-term overloads.

| Parameter | Specification |

|---|---|

| Adhesion | Excellent adhesion to polymeric insulation, connectors, and metallic components |

| Material | Thermally stabilized polyolefin blend with high-permittivity additives |

| Tensile Strength | 0.1 MPa |

| Volume Resistivity | ≥ 1 × 10¹³ Ω·cm |

| Elongation at Break | ≥ 250% |

| Self Fusing Property | Forms a homogeneous, void-free mass under pressure |

| Operating Temperature | –40 °C to +100 °C (continuous) |

| Permittivity/Dielectric Constant | ≥ 15 |

Applications

Selection Criteria

To identify the correct kit configuration, kindly confirm the following project details:

01

CSCM-1 – 25 mm width, 2 mm thickness, 300 mm length

02

CSCM-2 – 30 mm width, 2 mm thickness, 300 mm length

03

CSCM-3 – 30 mm width, 3 mm thickness, 400 mm length

04

Other sizes available on request

05

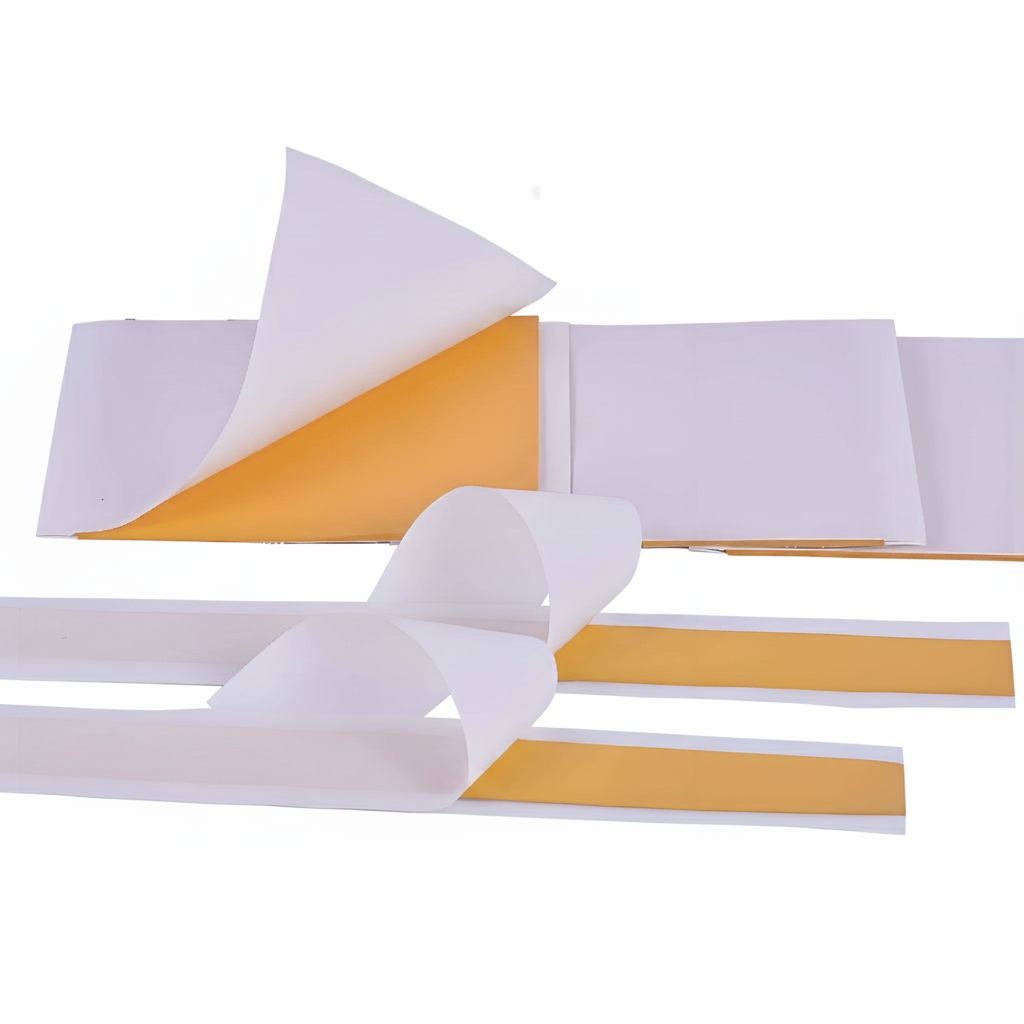

Supplied as strips or rolls with release paper on both sides

06

Recommended storage: In original packaging, protected from moisture, dust, heat, and direct sunlight

Need Help?

Our experts are ready

Our experts are available for on-site support, remote

guidance and tailored engineering.

It relieves electrical field stress at insulation cut-backs, connectors, and screen terminations, reducing the risk of partial discharge and insulation failure in MV/HV cables.