Heat Shrink and Cold Shrink Technology

Heat Shrink and Cold Shrink Technologies are an indispensable part of the power cable industry as they contribute to the development of power infrastructure. While both heat shrink and cold shrink technologies are used for jointing power cables, they both have their pros and cons in specific situations.

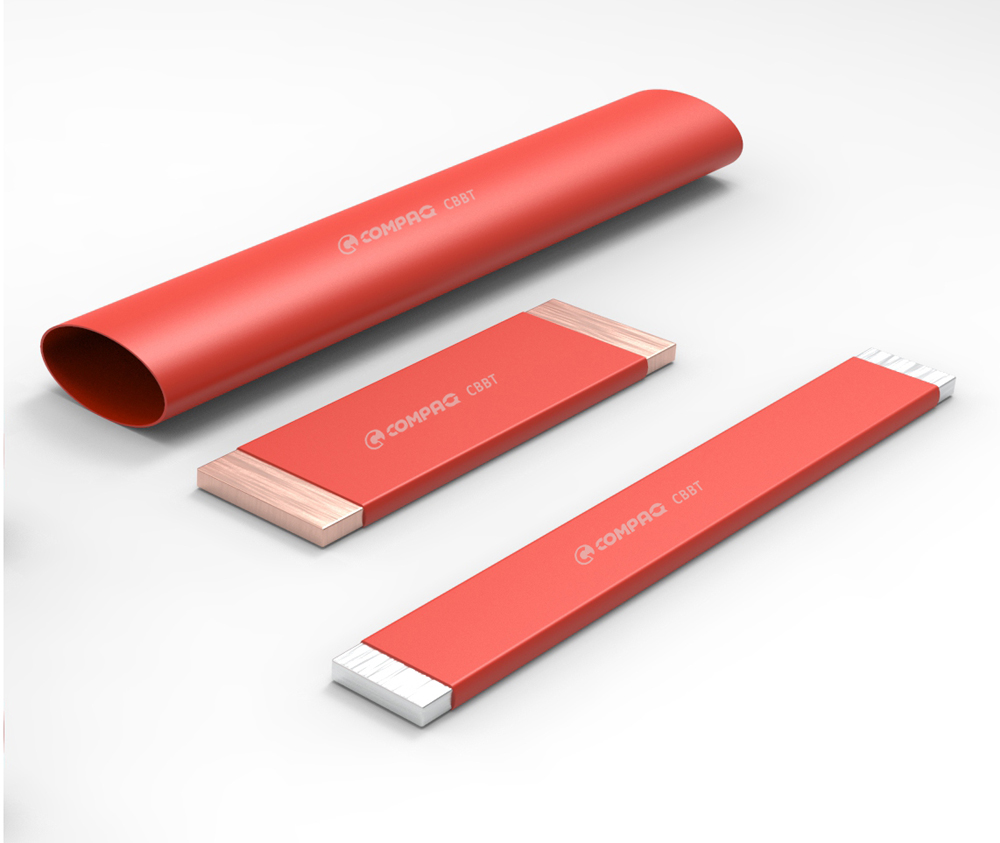

Compaq International produces different types of high-quality, durable, and reliable cable accessories which can be heat shrink or cold shrink technologies. Both types of technologies are proven to provide years of service without needing maintenance.

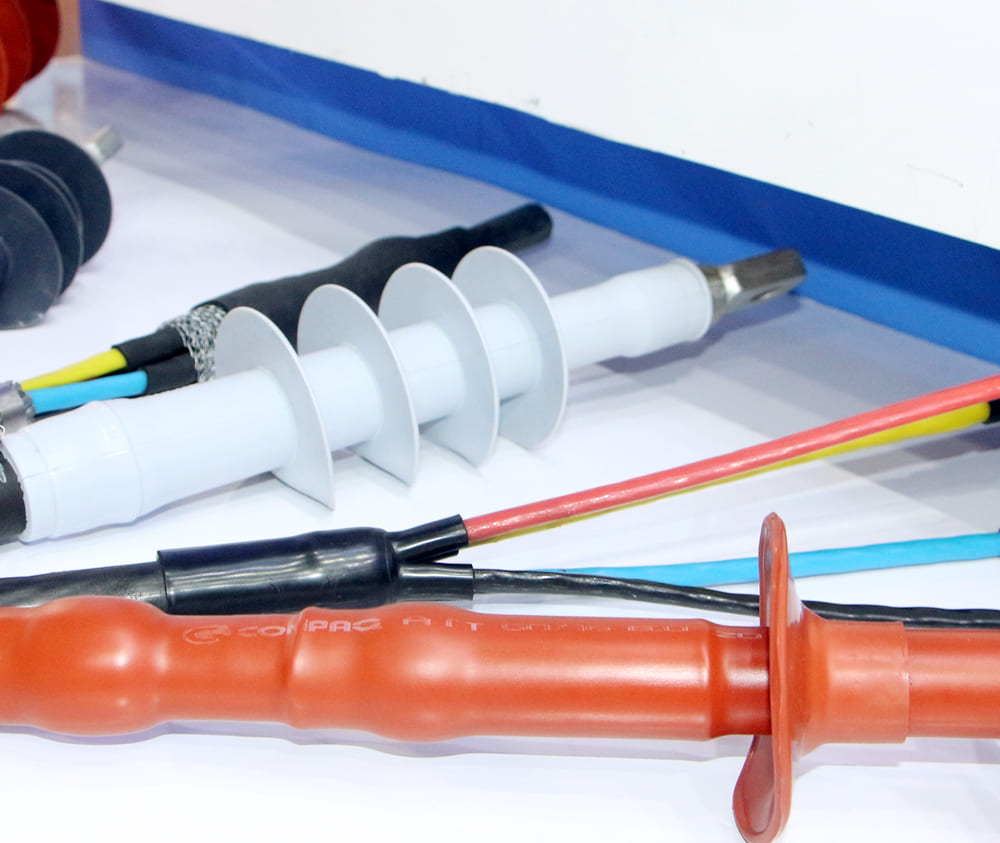

Here is a glimpse of how Compaq International’s covers heat shrink and cold shrink technologies -

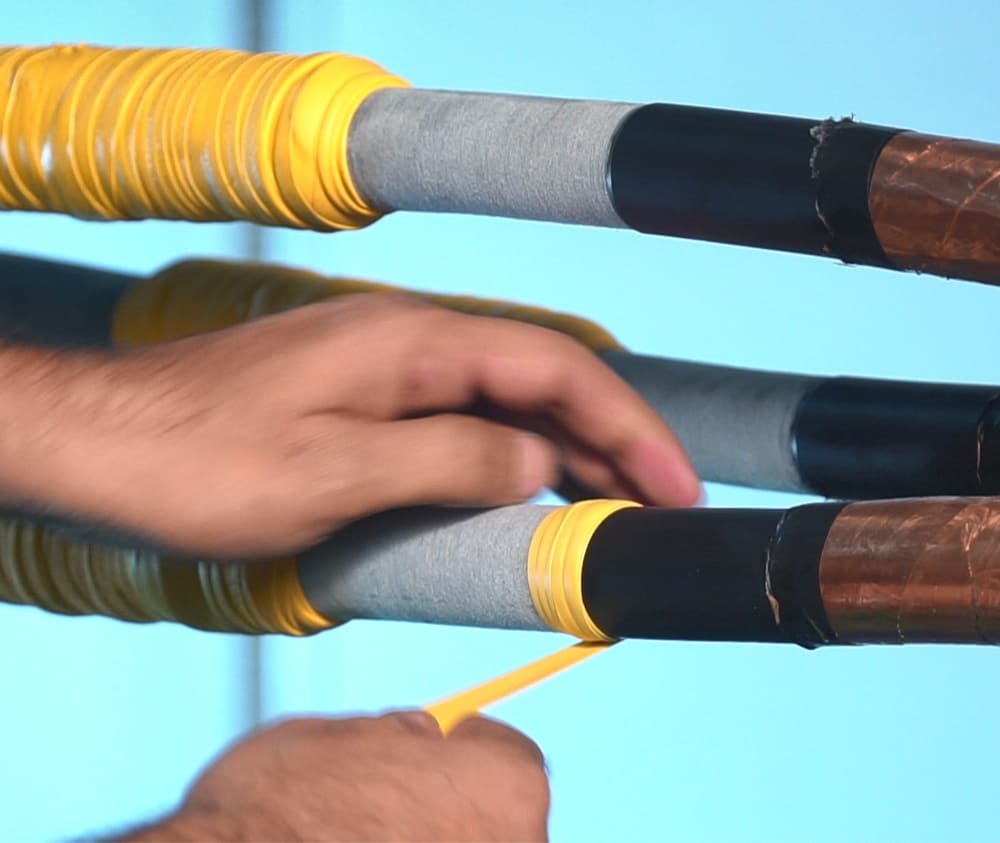

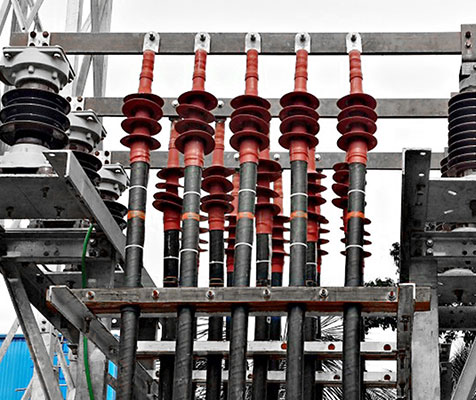

Heat Shrink Technology

Compaq International began its operation with heat shrink technology 23 years ago and they perfected it for field usage. The brand uses specially formulated thermoplastic polymer materials that have the capability to shrink and conform with precision to different shapes. Elastic memory uses cross linking that allows them to return to their original shape after heat application. Within the advanced heat shrink product range, multi-layer tubing and unique materials science incorporate several functions into each component.

Compaq International’s heat shrink products have a proven track records without maintenance which translates into massive cost savings. These products are built for robustness - they are capable of sustaining in the harshest of weather conditions and are also resistant to chemicals.

Salient Features:

1. Flame Retardant

2. Superior reliability

3. Resistance to thermal ageing

4. Hydrophobicity

5. Tracking and erosion resistance.

6. High thermal property

7. Resistance to surface electrical activity

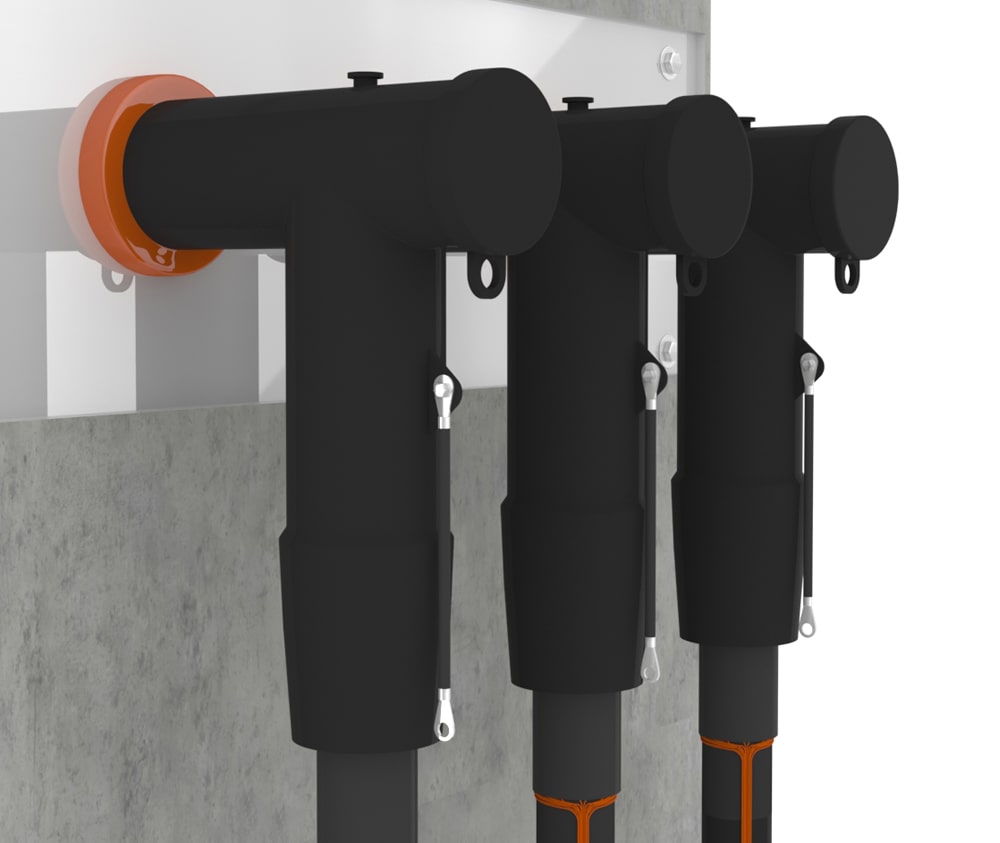

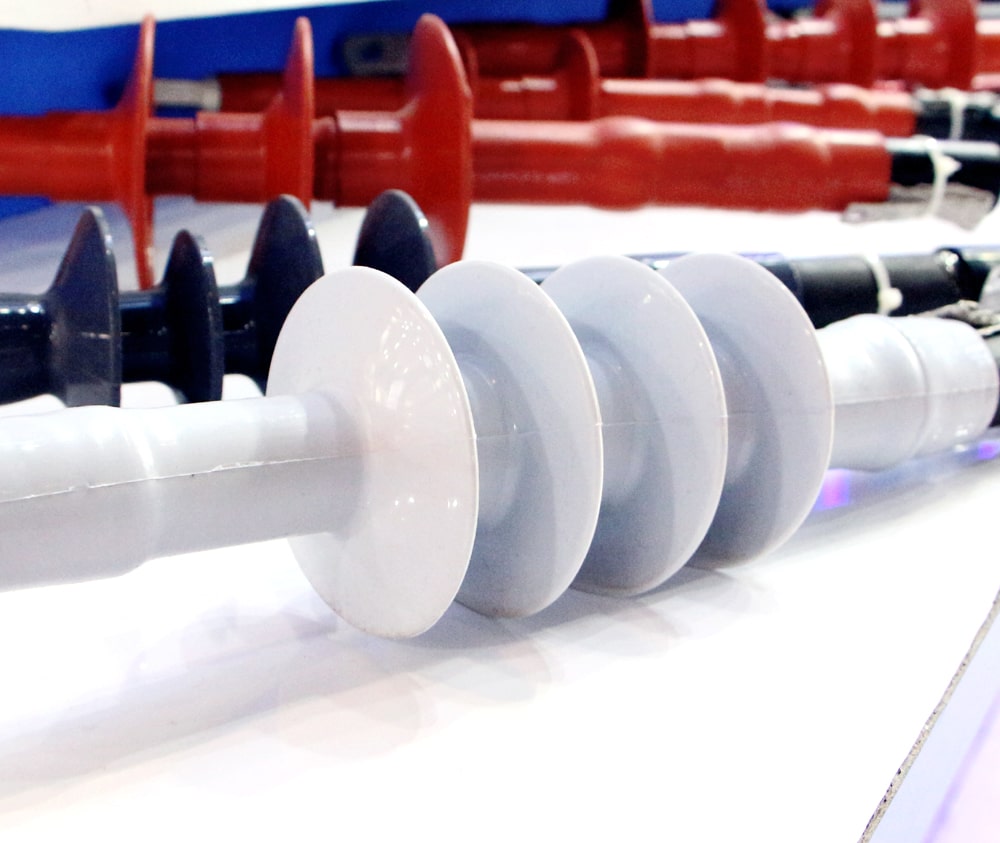

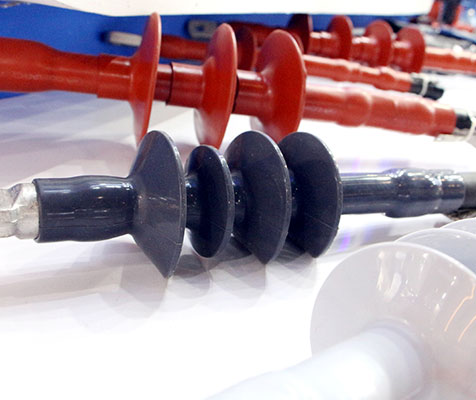

Cold Shrink Technology

In situations where heat shrink technology is unsuitable, cold shrink technology comes to the rescue of power projects. In places with extreme weather conditions or unsafe environments such as areas around gas pipelines, cold shrink technology products are a safer option.

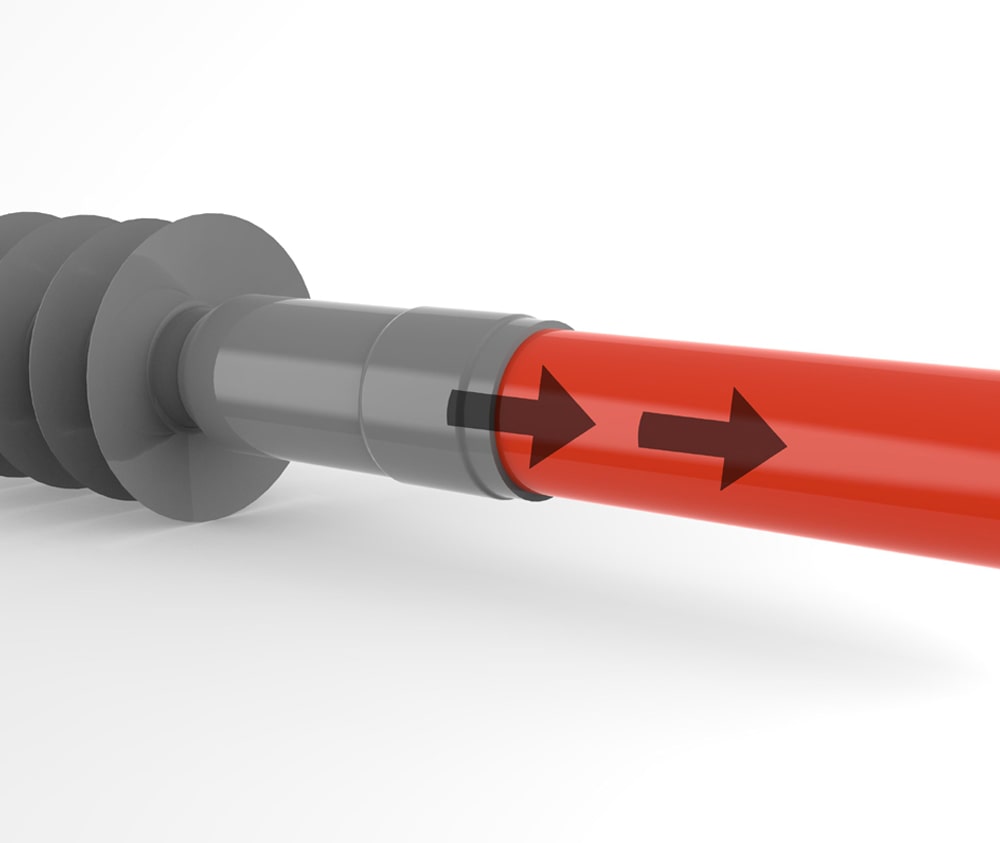

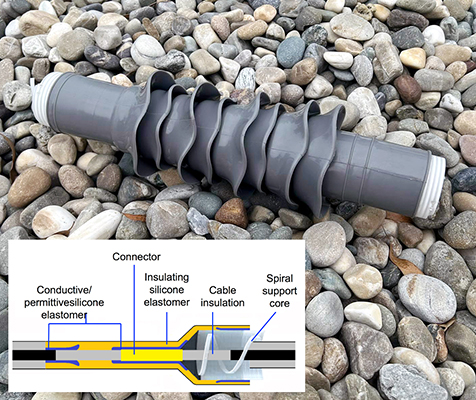

Compaq International’s cold shrink products, made from silicone or ethylene propylene diene monomer (EPDM) are excellent at connecting and sealing power cables. The cold shrink tubes come fitted with a spiral cord inside of them. When a tube is positioned over a desired place, the spiral in the tube is pulled out, which causes the tube to shrink to its pre-stretched size. The tube thus fits the cable perfectly and constantly exerts radial pressure for the lifetime of the joint or termination.

Compaq International’s cold shrink technology products also have a proven track records in field. The silicone rubber used in the products is reliable for use in the higher voltage classes, and it conforms well to cable bends, which is suitable for long term usage and protecting against moisture ingress, or voids within the installation. Cold Shrink products are suitable for use in refineries, coastal environments, high altitude environments, underwater environments, solar power plants and wind farms.

Salient Features:

8. Flame Retardant

9. Resistance to thermal ageing

10. Hydrophobicity

11. Tracking and erosion resistance.

12. High thermal property

Do you have a requirement for heat shrink or cold shrink cable accessories for your running projects? Compaq International is among the industry leaders for power cable accessories such as cable joints and cable terminations. The company manufactures products that use both heat shrink and cold shrink technologies with highly precise measurements. We not only provide top-notch products, but also unparalleled after-sales service. To inquire about our products, get in touch with us here - https://www.compaqinternational.com/contact.php

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

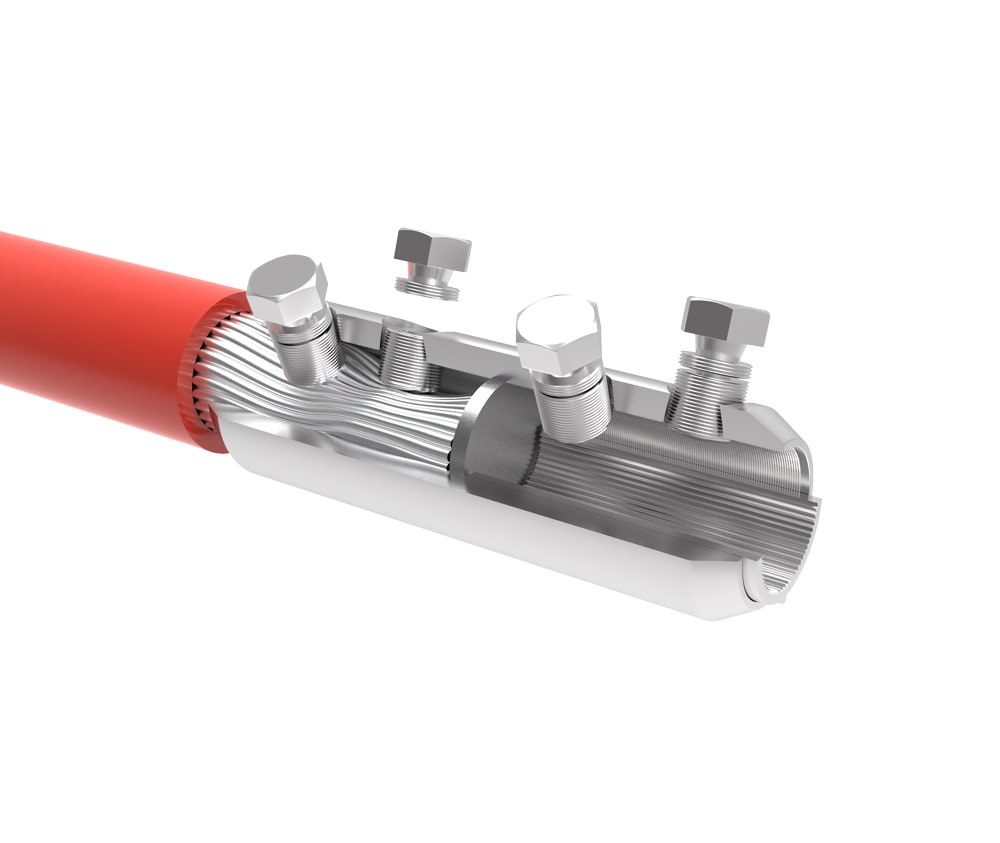

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?