In the renewable energy sector, turbines and solar panels capture attention. Yet beneath the surface lies an equally critical component: the cable accessories- cable joints, cable terminations, and separable connectors which quietly dictate system reliability.

Why Cable Accessories Are the Unsung Critical Component

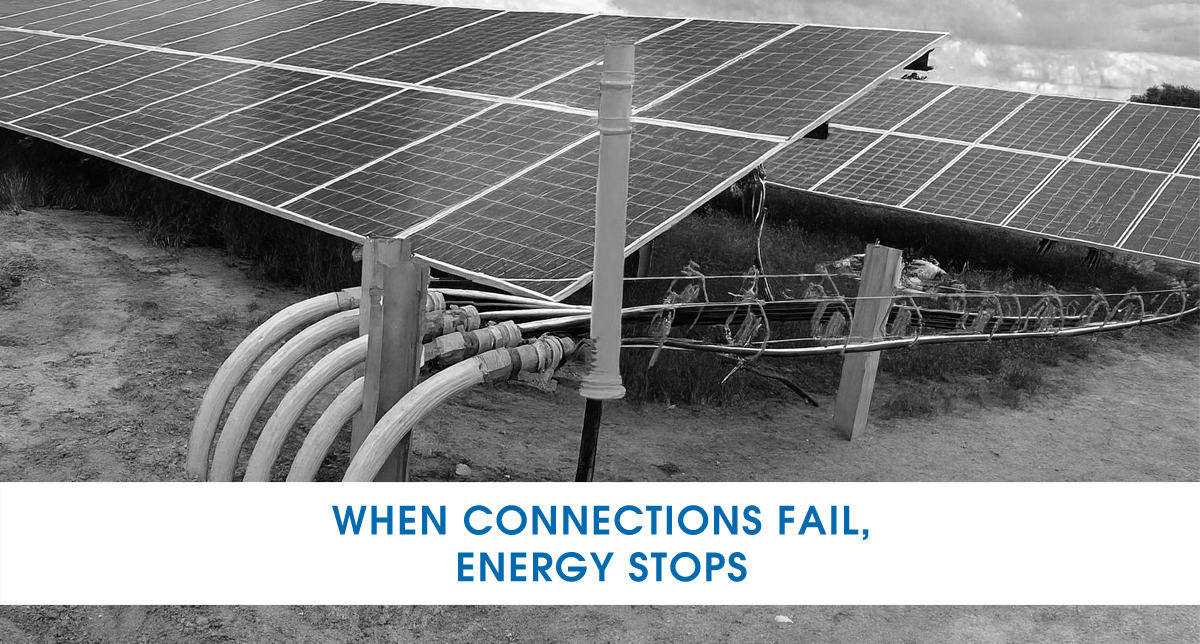

When you stand at a wind farm or solar plant, the majesty of rotating blades and gleaming panels is undeniable. But it’s what you can’t see, the underground cables and their connections that often become the weakest link in the system.

Every joint or termination must maintain perfect sealing under vibration, thermal cycling, soil movement, moisture, and contamination. Even a tiny flaw or void that allows moisture or air ingress can lead to catastrophic failure over time.

- In wind farms, cables endure constant bending, vibration, and temperature swings as they descend the towers.

- In solar arrays, long underground runs face soil pressure, moisture ingress, shifting terrain, and occasional digging.

At every connection point, the margin for error is minimal. A single accessory failure can disable an entire string of panels or cause a turbine to go offline. The cost in lost production, repair, and reputation is far greater than the price of a robust accessory.

The Human Factor: Installation & Component Selection

Even the best technology fails if installation is flawed. Many system failures can be traced back to:

- Inappropriate or low-quality accessories selected purely for cost savings

- Poor training or improper procedures during installation (surface cleanliness, precise geometry, sealing technique)

- Overlooking the necessity of post-installation verification and testing

At COMPAQ International, we believe the product is only half the equation- expertise, support, and verification make the difference.

COMPAQ’s Commitment to Reliable Connections

With over 27 years of experience, COMPAQ designs and delivers high-quality cable accessories with stringent testing and field support.

Key differentiators:

- Robust designs: Our heat-shrink and cold-shrink solutions are engineered for harsh environments from offshore wind to desert installations.

- Performance validated: Every product is tested up to 66 kV under lab and field conditions to confirm consistency and durability.

- End-to-end support: We provide training, site consultancy, diagnostic services, and ongoing guidance to ensure field installations meet the intended specifications.

By combining quality materials, rigorous testing, and trained execution, we transform what might be the weakest link into a reliable, resilient component of the renewable energy system.

Reliability Lies Underground

Renewable energy’s promise depends not just on what lies above ground — it depends on the connections below. Well-engineered, expertly installed accessories ensure projects remain safe, efficient, and profitable over their entire lifetime.

At COMPAQ International, we stand behind every connection because true reliability is built not by visible assets alone, but by the invisible bonds beneath the earth’s surface.

For further information about our cable accessory solutions, contact us at info@compaqinternational.com.

Frequently Asked Questions

- Why are cable accessories considered the “weak link” in renewable energy systems?

Because joints and terminations are exposed to stress, moisture, vibration, and soil movement. Any flaw in these components can trigger system failure, making them critical despite their small size.

- What environmental stresses do cable accessories face in wind and solar installations?

They must manage vibration, thermal cycling, soil swelling or shifting, moisture ingress, contamination, UV exposure (for exposed parts), and mechanical disturbance.

- How much impact does one accessory failure have on a renewable energy installation?

A single joint or termination failure can disable an entire string of solar panels or shut down a turbine line, causing high repair costs and lost revenue during downtime.

- How does installation quality affect accessory reliability?

Even premium accessories fail under poor installation. Precision, cleanliness, proper sealing technique, and field verification are mandatory for reliable performance.

- What sets COMPAQ’s cable accessory solutions apart in the renewable energy sector?

COMPAQ offers engineered accessories validated up to 66 kV, combined with rigorous testing, field-level training, consultancy, and diagnostic services to ensure reliable deployment.

- How should renewable project developers assess cable accessory reliability?

They should request test reports, factory quality certifications, compliance with international standards (IEC, HD), and opportunities for on-site verification or third-party audits.