Types

Position

Layout

blog

The reliability of a medium-voltage power network hinges on the integrity of its simplest components. For electrical engineers and infrastructure specifiers, selecting the correct cable jointing kit for 11kV and 33kV applications is a critical decision that impacts safety, operational continuity, and total cost of ownership.

This guide provides a formal yet clear overview of the technologies, standards, and selection criteria necessary to make an informed, confident purchasing decision in line with current industry best practices.

A cable joint is a precision-engineered system designed to perform three essential functions:

A joint failure can result in catastrophic network failures, prolonged outages, and significant financial loss. The selection process is therefore a matter of both technical precision and operational risk management.

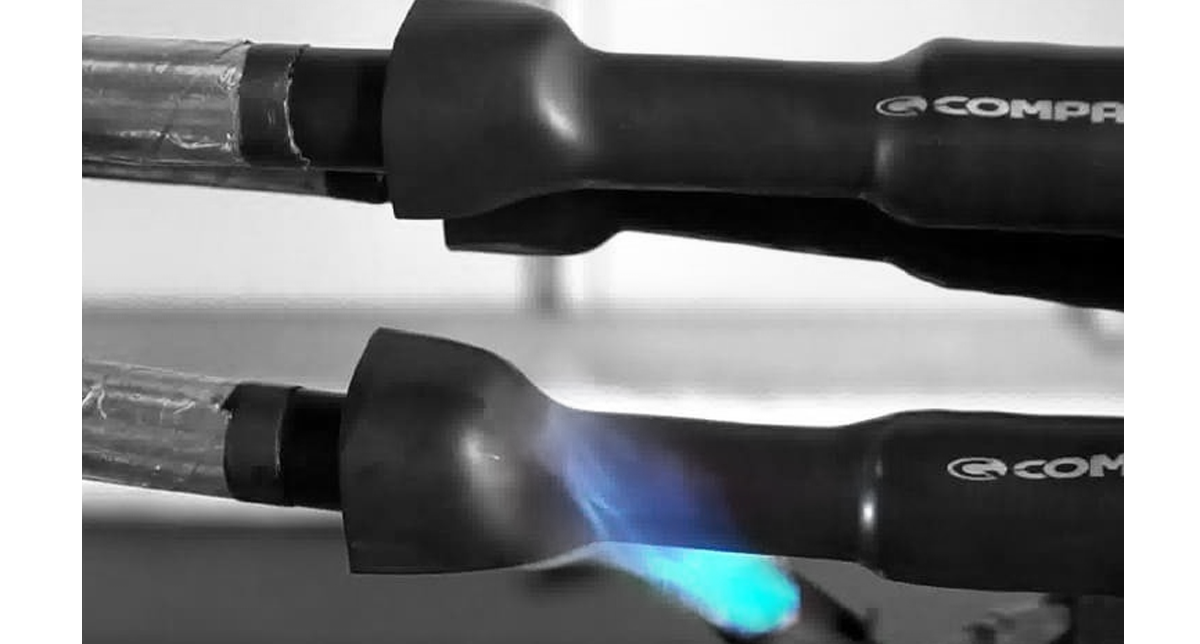

The choice between technologies is guided by application, installation constraints, and utility standards. The three principal systems are:

A rigorous selection process must assess the following parameters against your project specifications:

|

Criteria |

Technical Detail |

|

Rated Voltage & Category |

Must be suited for the system voltage (e.g., 12/20(24)kV or 20/36(42)kV). |

|

Cable Compatibility |

Designed for specific insulation types (XLPE/EPR) and constructions (armoured, unarmoured, single/core). |

|

Conductor Specification |

Compatibility with copper or aluminium conductors and their cross-sectional area range. |

|

Connector System |

Integration with the required connector type (e.g., shear-bolt, compression). |

|

Screening Continuity |

Method for restoring the electrical screen (e.g., copper wire mesh, tape, or conductive layers). |

|

Sealing Performance |

Type of sealing system (masticS, barriers) and its suitability for the environment (e.g., submerged, underground). |

|

Compliance & Certification |

Mandatory independent certification to international standards (IEC 60502-4). |

Adherence to IEC 60502-4 is the unequivocal benchmark for quality and performance in medium voltage cable accessories. These standard mandates a suite of rigorous type tests designed to simulate decades of operational stress, including:

Procuring products with independent IEC 60502-4 certification is the most effective strategy to mitigate the risk of in-service failure.

Ultimate reliability is derived not only from product design but from the manufacturer's commitment to quality and expertise. A trustworthy partner demonstrates this through:

COMPAQ International designs and manufactures medium voltage jointing kits to the highest standards of engineering excellence. Our product range is developed for professionals who specify with confidence and require unwavering performance.

Our 11kV and 33kV jointing kits are characterized by:

We are committed to providing not just products, but fully supported engineering solutions.

The selection of a cable jointing system is a fundamental investment in network resilience. By prioritizing independently certified products, appropriate technology, and manufacturers with demonstrable expertise, engineers can ensure that these critical components perform as intended for the long term.

For detailed technical dossiers, type test certificates, or application-specific consultation, please contact our engineering team.

Email: info@compaqinternational.com

Need Help?

Our experts are ready

Our experts are available for on-site support, remote

guidance and tailored engineering.