Types

Position

Layout

blog

As global power systems advance toward smarter, denser, and safer grids, every detail of electrical connectivity matters. One of the most significant advancements in this domain is the mechanical shear-head lug and connector- a technology that replaces the traditional crimping process with precision-controlled torque.

At COMPAQ International, we view this as more than an innovation in installation- it is an evolution in how modern electrical networks ensure consistency, reliability, and safety across every connection point.

For decades, crimping has been the standard practice in cable terminations. While effective, it depends heavily on operator skill, tool condition, and die selection. Variations in pressure or crimp depth can lead to inconsistent performance, higher contact resistance, or premature failure.

In contrast, mechanical shear-head connectors bring repeatability and precision into every installation. Each connector is designed with pre-calibrated shear bolts that automatically shear off at a defined torque level- applying the exact pressure required for optimal conductor contact. This eliminates guesswork, minimizes human error, and ensures that every joint performs with the same mechanical integrity.

The result is a uniform, gas-tight, and low-resistance connection, independent of the installer’s skill or external conditions.

The principle is elegantly simple yet technically robust:

This creates a consistent electrical and mechanical interface between conductors — without the need for hydraulic tools or special dies. The system performs reliably under cyclic loads, temperature variations, and vibration — common in substations, renewable energy plants, and heavy industrial sites.

These attributes make COMPAQ’s shear-head connectors a preferred choice where long-term reliability and installation speed are equally critical.

This ensures a uniform installation philosophy across all voltage classes- from 11 kV to 72.5 kV, simplifying logistics for EPC contractors, utilities, and maintenance teams.

Shear-head connector technology is now widely deployed in:

Their consistent performance, even in challenging site conditions, has positioned them as the new standard for critical power infrastructure.

For more than 25 years, COMPAQ International has combined engineering expertise, material innovation, and manufacturing excellence to deliver products that define reliability.

Every shear-head connector we produce is:

At COMPAQ, innovation is guided by one principle: to make every connection safer, smarter, and more dependable- for decades of service life.

The next generation of power networks will demand components that combine mechanical strength, environmental resilience, and installation simplicity. Shear-head technology aligns perfectly with this vision.

Future innovations will continue to refine torque calibration, surface coating systems, and conductor interface geometry- extending performance under higher voltages and demanding load profiles.

COMPAQ International remains committed to driving this evolution- engineering connection systems that deliver measurable reliability in every circuit, every grid, and every country we serve.

1. What distinguishes mechanical shear-head connectors from traditional crimp connectors?

They use pre-calibrated bolts that shear off at defined torque, ensuring consistent compression and eliminating dependency on operator skill or hydraulic tools.

2. Are COMPAQ shear-head connectors suitable for both aluminium and copper conductors?

Yes. They are universally compatible, featuring bi-metallic interfaces that prevent galvanic corrosion and ensure stable long-term conductivity.

3. What voltage levels can these connectors support?

They are designed for low, medium, and high-voltage applications up to 72.5 kV, making them ideal for a broad range of power systems.

4. Do they comply with international standards?

All COMPAQ mechanical connectors are rigorously tested in accordance with IEC 61238-1 and relevant international norms.

5. Can they be integrated with other COMPAQ accessories?

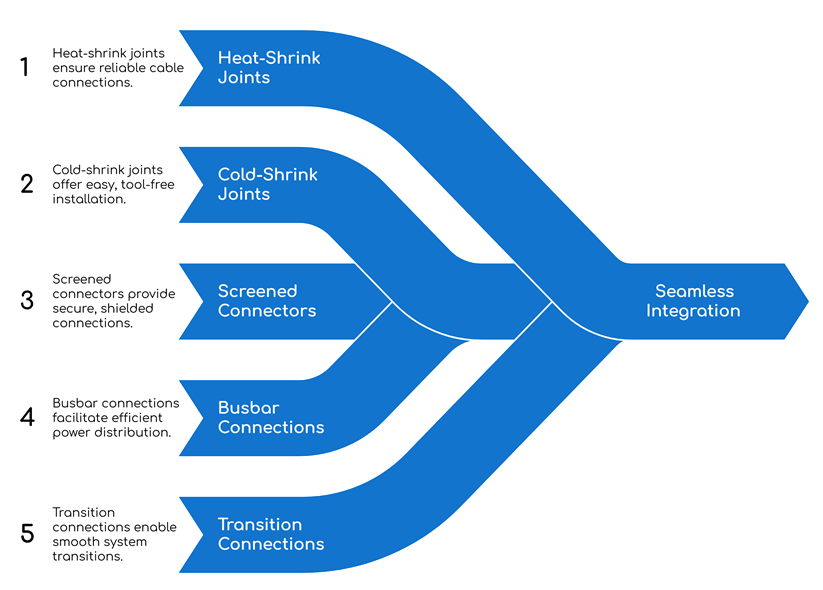

Absolutely. They are fully compatible with COMPAQ’s heat-shrink, cold-shrink, and separable connection systems.

For more information about mechanical shear head lugs or connectors write at info@compaqinternational.com

Need Help?

Our experts are ready

Our experts are available for on-site support, remote

guidance and tailored engineering.