In modern power distribution systems, cable joints play a critical role in ensuring efficient and reliable connectivity between cables. Among the various types of joints available, pre-moulded slip-on (or push-on) cable joints stand out for their simplicity, efficiency, and superior performance. This blog delves into the technology, applications, and benefits of pre-moulded slip-on cable joints, providing a comprehensive understanding for professionals in the power and electrical industry.

What Are Pre-moulded Slip-On Cable Joints?

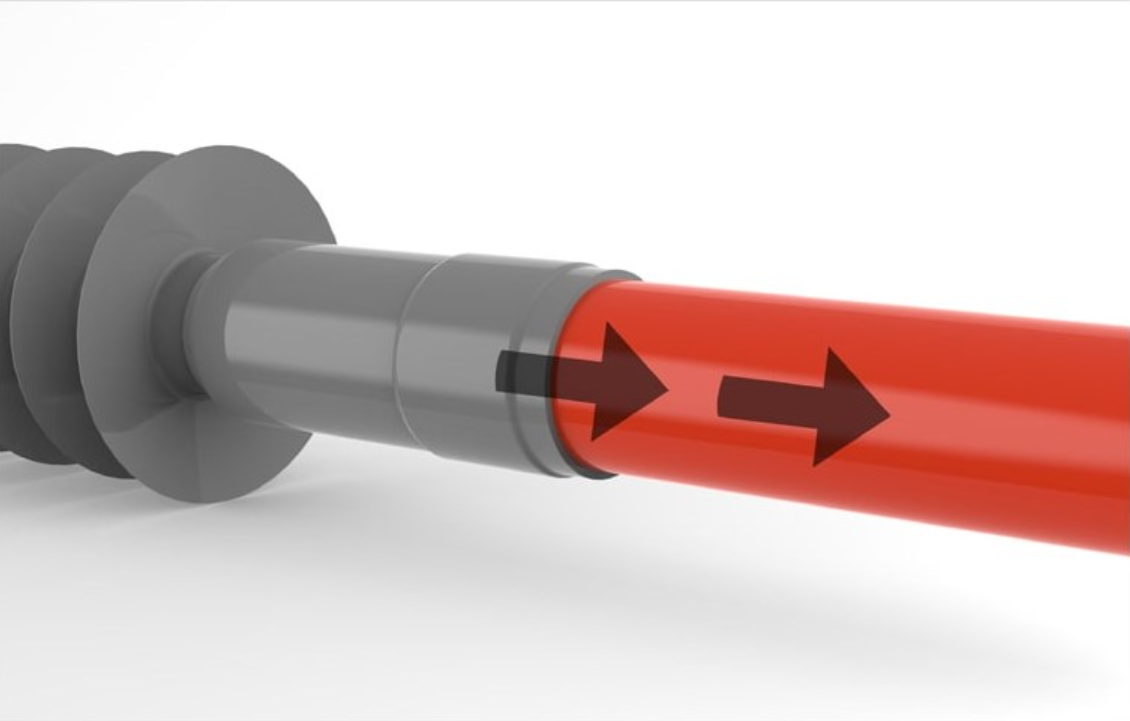

Pre-moulded slip-on or push-on cable joints are pre-engineered, factory-moulded insulation systems designed to connect two or more cables seamlessly. Unlike traditional methods requiring field-applied tapes, heat shrink, or cold shrink processes, these joints come pre-moulded in their final shape. Installation involves simply “pushing” or “slipping” the joint onto the prepared cable ends.

Key Features of Pre-moulded Slip-On Joints

- Factory Engineered for Precision

Made using high-performance elastomeric materials like EPDM or silicone rubber. Molded in factory conditions, guaranteeing consistency and removing installation guesswork.

- High Dielectric Strength

Delivers robust electrical insulation for safe operation under high-voltage scenarios—supporting up to ~72.5 kV systems.

- Integrated Stress Control

Built-in stress control technology balances electrical stress at the cable ends, reducing breakdown risks.

- Compact and Lightweight Design

Ideal for installation in tight or complex environments, cutting down both weight and hassle.

How Do Pre-moulded Slip-On Joints Work?

- Cable Preparation: Strip and prep cable per manufacturer’s guidelines to ensure clean conductor and insulation surfaces.

- Stress Control Application: Apply additional stress mitigation components if the design requires it.

- Sliding the Joint: Lubricate the joint with approved non-conductive grease, then slip it over the cable ends.

- Alignment: Position the joint correctly for optimal performance.

- Testing & Commissioning: Conduct electrical testing post-installation to ensure system readiness.

Advantages of Pre-moulded Slip-On Joints

- Ease of Installation: No need for heat application or specialized tools—quick and easy setup.

- Enhanced Reliability: Factory molding removes variability from field installation, ensuring uniform performance.

- Maintenance-Free Operation: Built for durability—minimal inspection or upkeep needed.

- Wide Application Range

Compatible with XLPE, PILC, EPR-insulated cables. Perfect for utilities, industry, renewables, and urban power networks.

Application Scenarios for Pre-moulded Slip-On Joints

- Medium- and high-voltage power transmission networks—substations, wind farms, underground grids.

- Power distribution in industrial setups and manufacturing facilities.

- Renewable energy deployments—solar farms, wind energy systems where installation speed matters.

About Compaq’s Pre-moulded Slip-On Cable Joints

Compaq International delivers top-tier pre-moulded slip-on cable joints crafted for demanding applications. Built with robust materials, customizable for varied cable types, and rigorously tested to meet international standards (e.g., IEC, CENELEC), our joints are the smart, dependable choice for seamless power delivery. For more information about COMPAQ Pre-Moulded/SlipOn cable jointings kits and solutions write us at info@compaqinternational.com