Types

Position

Layout

Product Overview

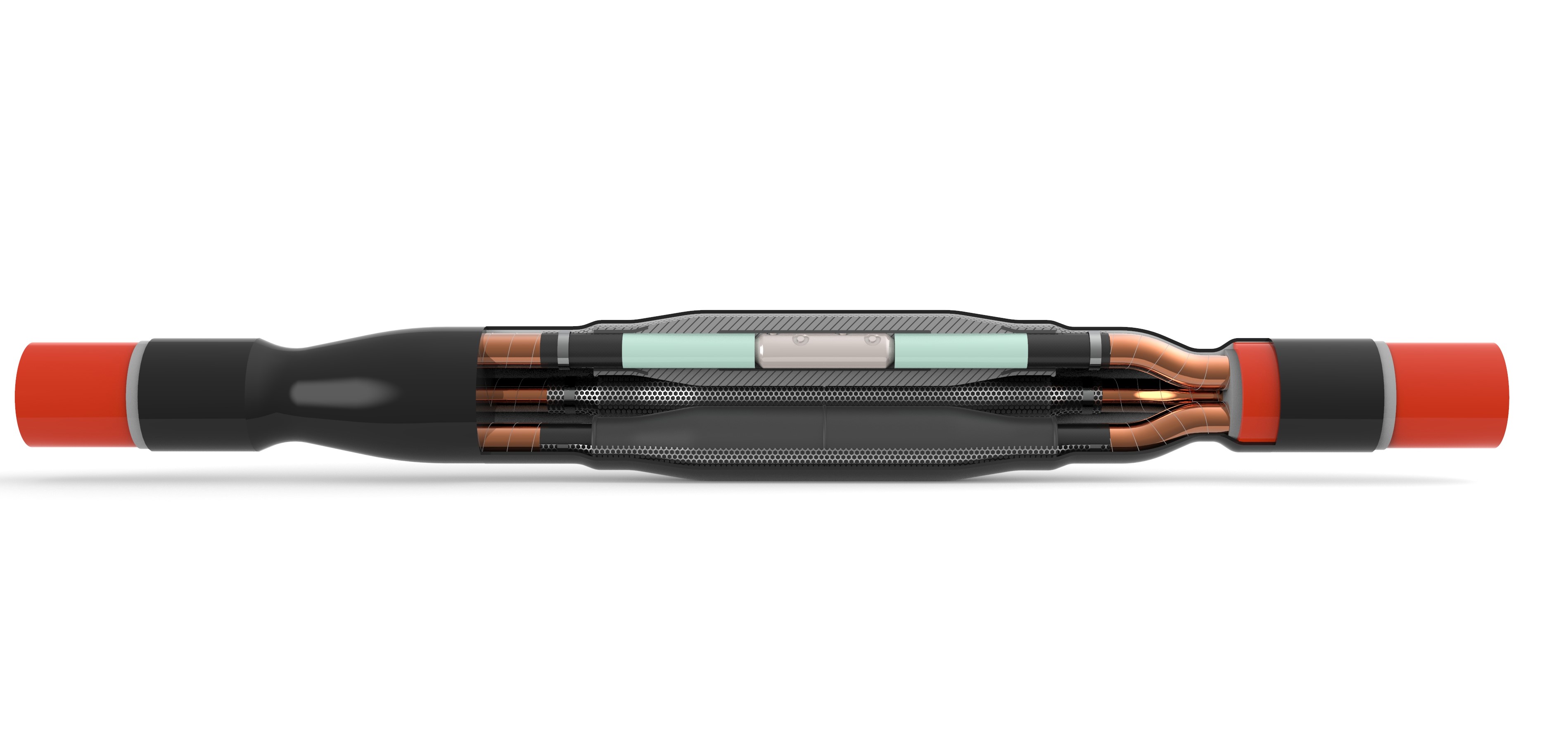

The CCSJ Cold Shrink Straight Joint is a high-performance solution for straight jointing of medium-voltage cables up to 42kV. Manufactured from premium silicone rubber and supplied in a pre-expanded design, it enables fast, tool-independent installation while ensuring long-term electrical and mechanical reliability.

Featuring integrated stress control, excellent resistance to partial discharge, thermal short-circuit, and electrical heat cycling, the CCSJ is designed for demanding indoor and outdoor network conditions. With just three sizes covering conductor ranges from 185 mm² to 1000 mm² and compatibility with multiple connector types, it offers a compact, versatile, and dependable jointing solution for modern MV power systems.

Cold shrink technology eliminates the need for heat or special tools, reducing installation time and site risk.

Factory-controlled expansion ensures uniform radial pressure and reliable electrical contact throughout service life.

Built-in stress control system minimizes electrical stress enhancing insulation integrity and joint longevity.

Only three joint sizes cover conductor cross-sections from 185 mm² to 1000 mm² simplifying selection and inventory.

Proven resistance to partial discharge, impulse voltage and AC/DC withstand voltages under severe conditions.

Excellent performance in wet, humid, and harsh environments, suitable for both indoor and outdoor installations.

Durable silicone rubber construction ensures long-term, trouble-free service with minimal maintenance.

| Parameter | Specification |

|---|---|

| Rated Voltage | Up to 42kV |

| Conductor Type | Copper or Aluminium |

| Cable Construction | Armoured / Unarmoured, Screened / Unscreened |

| Core Configuration | Single-core and Three-core |

| Installation Method | Cold Shrink – Pre-expanded tubing |

| Joint Body Material | High-performance Silicone Rubber |

| Standards Compliance | IEC 60502-4, IS 13573, HD 629.1 |

| Cable Insulation Type | XLPE or EPR |

| Connector Compatibility | Compression and Mechanical (Shear Bolt) |

| Environmental Resistance | UV, ozone, moisture, pollution, thermal cycling |

Applications

Selection Criteria

To identify the correct kit configuration, kindly confirm the following project details:

01

System voltage

02

Cable insulation type (XLPE or EPR)

03

Number of cores and conductor size

04

Cable construction (armoured/unarmoured)

05

Connector preference (mechanical or compression)

06

Installation environment (indoor, outdoor, underground)

Need Help?

Our experts are ready

Our experts are available for on-site support, remote

guidance and tailored engineering.

No. The cold shrink design eliminates the need for heat, flame, or special installation tools, making it safer and faster to install, especially in confined or sensitive areas.

They are tested and certified according to IEC 60502-4, IS 13573, CENELEC HD 629.1 and are RoHS compliant.

The CCSJ is designed for straight-through jointing of XLPE insulated medium-voltage power cables up to 42 kV, covering conductor sizes from 185 mm² to 1000 mm².

Absolutely. Its quick installation, high reliability, and resistance to harsh environments make it ideal for solar, wind, and other renewable energy installations.

Each kit includes the silicone rubber joint body, conductor connector, outer protective sleeve, installation accessories, and detailed assembly instructions.