Types

Position

Layout

Product Overview

COMPAQ CSCP is a precision-engineered elastomeric High-K Stress control patch developed for medium and high voltage cable joints and terminations up to 72.5kV.

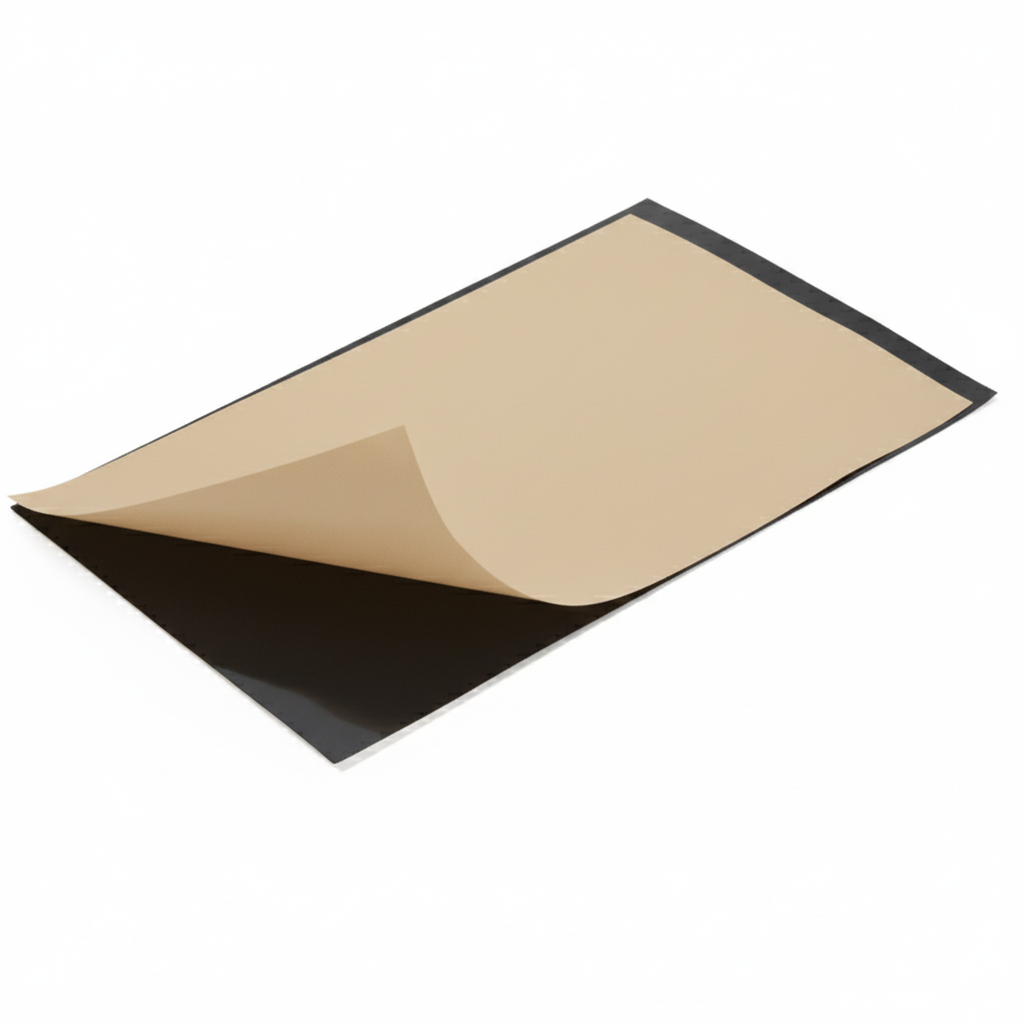

Unlike conventional stress-grading mastics, CSGP-HV is supplied as a pre-formed, cross-linked elastomeric sheet with a protective release liner enabling quick and clean application directly over the semiconductive screen cut-back or ferrule region.

Its controlled high-permittivity formulation redistributes electric-field intensity ensuring a uniform potential gradient and preventing partial discharge (PD), surface tracking, or insulation degradation.

The patch combines precise dielectric thickness, void-free adhesion, and moisture sealing, ensuring long-term operational stability under the electrical, thermal, and environmental conditions typically up to 66/72.5 kV jointing and terminating systems.

Integration of CSCP into COMPAQ-approved jointing and termination kits enhances dielectric reliability, maintains PD levels < 5 pC, and extends service life across transmission & distribution, renewable energy, and utility networks.

Replaces kneadable mastics with a pre-calibrated high permittivity dielectric sheet to balance electrical stress in HV joints and terminations up to 72.5kV.

Factory controlled dimensions ensure consistent field grading geometry and predictable dielectric strength in every installation.

Delivered with a double sided release liner no mixing, kneading, or contamination during assembly, ideal for on-site or clean room use.

Maintains dielectric and adhesion properties from –40 °C to +100 °C and withstands short-term overloads up to 130 °C.

Provides an additional sealing layer around ferrules/connectors and screen cutbacks, preventing ingress of humidity, dust, and corrosive agents.

Designed and validated to support IEC 60502-4 and IEC 60840 system requirements for 66/72.5 kV class accessories.

| Parameter | Specification |

|---|---|

| Colour | Black / Dark Grey |

| Construction | High-K elastomeric patch with release liner |

| Tensile Strength | ≥ 1.0 N/mm² |

| Volume Resistivity | ≥ 1 × 10¹⁰ Ω·cm |

| Elongation at Break | ≥ 200 % |

| System Compatibility | 11 kV to 72.5kV systems |

| Operating Temperature | –40 °C to +100 °C (continuous) / 130 °C (short term) |

Applications

Selection Criteria

To identify the correct kit configuration, kindly confirm the following project details:

01

Cable voltage class (11 / 33 / 66 / 72.5 kV)

02

Connector type (mechanical/compression)

03

Accessory type (joint / termination)

04

Installation environment (indoor / outdoor / buried)

05

Required patch coverage length and width

06

Custom sizes available on request.

Need Help?

Our experts are ready

Our experts are available for on-site support, remote

guidance and tailored engineering.

High-K stress control patch has a dielectric constant allowing it to control voltage gradients effectively unlike standard sealants that provide only mechanical protection.

Fully. It is validated within COMPAQ’s 66/72.5 kV type tested systems as per IEC 60502-4 and IEC 60840.

It is applied at the screen-cut and ferrule area of MV and HV cable joints to equalize electrical stress and prevent insulation damage or partial discharge.

Yes. The cable surface should be clean, smooth, and dry to achieve full adhesion and effective electrical contact.

Selection depends on the voltage class, cable diameter, and joint design. COMPAQ provides pre-defined sizes such as 150 × 220 × 2 mm, or custom dimensions based on project requirements and system geometry.

Yes. CSCP patches can be applied during field refurbishment to improve the field-grading characteristics of aged or damaged insulation interfaces, provided surfaces are properly prepared.